Contract research in materials

and R&D projects with Coating Factory

We carry out contract research in the broad field of materials engineering. We study the microstructure, topography and surface morphology of materials and their properties such as strength, hardness, friction wear resistance, corrosion resistance, wettability or colour and gloss. We specialise in surface engineering, in particular PVD and PECVD coatings.

On the other hand, through R&D cooperation, we offer the development of new products using our staff and laboratory, as well as long-term research projects (with support for obtaining financing).

List of available apparatre:

- Tensile testing machine 2,5kN - Galdabini Quasar 2,5

- Tensile testing machine 25kN - Galdabini Quasar 25

- Reflectometer - Filmetrics F20

- Hardndess tester Brinell, Vickers Rockwell - FutureTech

- Nano hardness tester - Anton Paar NHT3

- Metallographic preparation

- Metallographic cutter - Hitech Europe C251 K

- Metallographic press - Hitech Europe EP 50PT

- Automatic metallographic polisher - Hitech Europe AP312KA

- Digital microscope - Hirox HRX-01

- Metallographic microscope - Zeiss AxioImager

- Optical Profilometer - Leica DCM8

- Multifunctional platform for tribological and mechanical properties testing - RTEC MFT-5000 The system functions as: Tribometer and Scratch tester

- Human hand simulator - Tribotouch

- Atomic force microscope - AFM NX10 by Park Systems

- Calotest - BAQ kaloMAX NT II S

- Goniometer - Osilla Contact Angle

- Salt test chamber - Ascott S1000ip

- Gloss and colorimeter - BYK-Gardner Spectro Guide 45/0

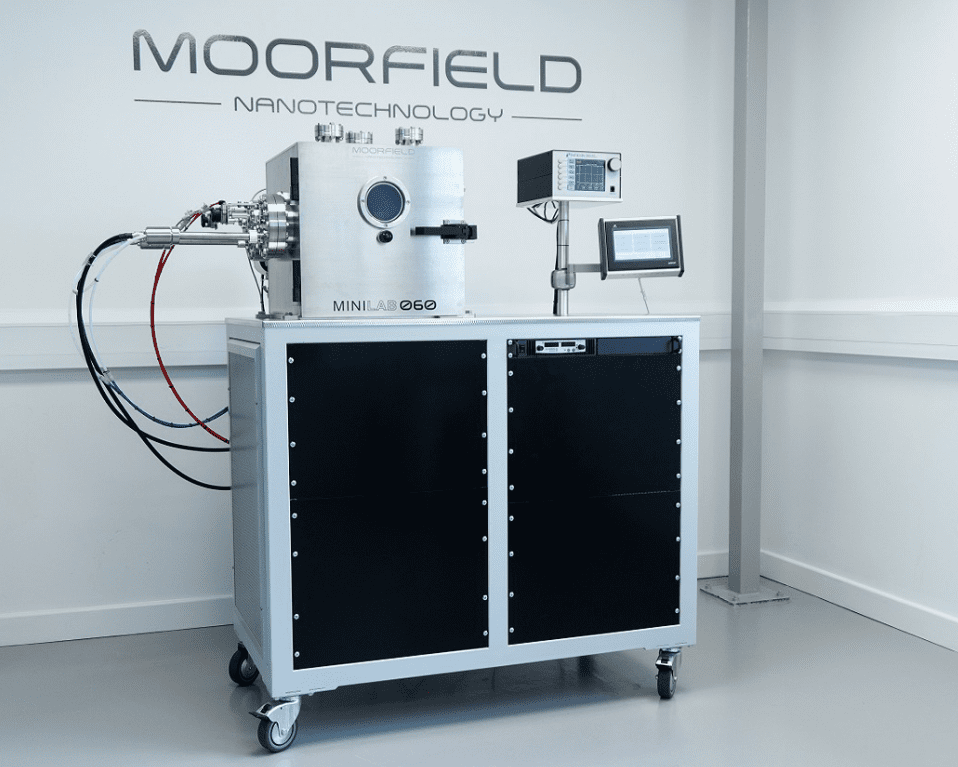

- Laboratory PVD - Moorfield Minilab 080

List of tests performed:

- Macroscale and micro/nano-scale testing of mechanical properties

- Corrosion tests

- Rockewell hardness

- Brinella hardness

- Vickers hardness

- Vickers microhardness

- Nanohardness

- Tribological wear tests, (ball-on-disc, pin-on-disc)

- Tribotouch friction wear resistance - human hand simulator

- Investigations into the morphology, surface topography and microstructure of materials

- Metallographic testing

- Macro examination on an optical microscope

- Micro examination on an optical microscope

- Atomic force microscopy (AFM) studies

- Profilometric testing

- Typical characterisation tests of coatings and surface layers

- Adhesion test of coatings, paints, adhesives

- Testing of optical properties: refractive index and absorption, reflectance, transmittance

- Coating thickness tests

- Wetting angle tests

- Surface energy test

- Gloss test

- Colour and hue test

- Coatings manufacture and process design

R&D cooperation starting process

Dedykowane laboratoryjne urządzenie

PVD do prac B+R (R&D)

Projektowanie procesu wytwarzania powłok i projektowanie powłok wraz z klientem. Aby móc prowadzić dla klientów projekty rozwoju produktów oraz projekty B+R (R&D), zainwestowaliśmy w dedykowane urządzenie PVD do nakładania powłok w skali laboratoryjnej. Charakteryzuje się ono dużą uniwersalnością i mniejszą komorą (względem urządzeń PVD w skali przemysłowej) ,dzięki temu obniżone są koszty procesów testowych, a samo urządzenie jest zawsze dostępne do badań.

Laboratory PVD equipment:

Moorfield Minilab 080

The system allows the production of coatings by PVD methods: magnetron sputtering and thermal evaporation. The unit is equipped with three 3′ magnetron sources and one source for thermal evaporation.

The system is equipped with quartz scales for ‘live’ coating thickness measurement and the ability to perform magnetron sputtering processes using both DC and radio frequency (RF) current. Due to the size of the chamber, the Minilab 080 allows for high coating quality and great potential in controlling process parameters to optimise the coatings produced and to produce multi-component/composite coatings.

Waldemar Furman

specjalista PVD

Have us carry out

PVD or PECVD coatings on your components

Michał Tarnowski

kierownik laboratorium

Outsource your materials research to us or

collaborate with us on an R&D basis on the development of coatingsa

Contact with us and

improve your product!